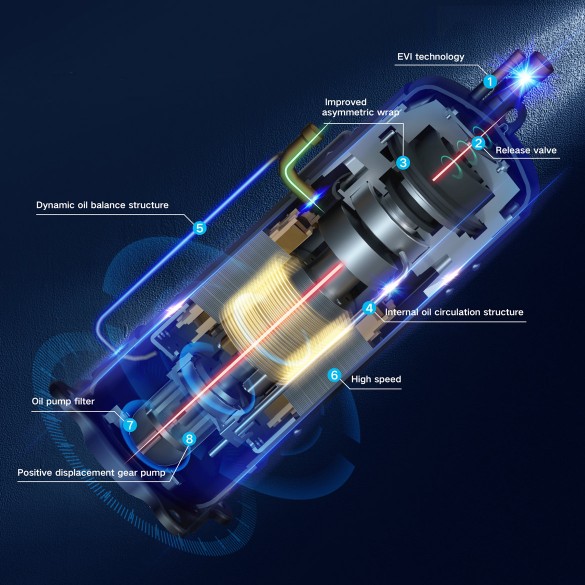

High Efficiency EVI Scroll Type DC Inverter High Pressure Cavity Compressor

1. High Efficiency EVI Control Technology

The high efficiency EVI Compressor is developed according to the requirements of the VRF unit. Its 0~420Hz adjustable range can perfectly match with the entire unit to push its performance to the greatest extent.

2. Release Valve

Improves partial load energy, adapting to the condition of the variable pressure ratio and upgrading compressor performance.

3. Improved Asymmetric Wrap

A new asymmetric wrap has been adapted, improving compressor efficiency by reducing internal leakage and invalid superheat.

4. Internal Oil Circulation Structure

Internal circulation of lubricating oil helps to reduce over-heat losses and oil discharge rate, improving efficiency and reliability.

5. Dynamic Oil Balance Structure

Uses advanced oil balance technology, with high reliability and flexible design without an installation limit. This can realise the parallel connection of compressors with different delivery capacities and revolving speeds.

6. High Speed

0~420Hz stepless inverter operation, with a wide adjustment range of capacity and precision of 1Hz.

7. Oil Pump Filter

Carries out filtration of any impurities to ensure that the oil supplied is clean.

8. Positive Displacement Gear Pump

Ensures the necessary oil supply regardless of the compressors revolving speed, improving the reliability of the compressor.